10/2024: EFFICIENT HEATING WITH THE NEW HEAT PUMP

10/2024: EFFICIENT HEATING WITH THE NEW HEAT PUMP

In the fall of 2024, we changed the heating method in part of the new hall. The old propane-butane air heater was replaced with a new electric heater powered by a new heat pump. This made heating more efficient and reduced our dependence on increasingly expensive gas.

04/2023: NEW UNIVERSAL MILLING MACHINE WITH INTEGRATED DIGITAL POSITION INDICATOR - OPTImill MT 200

04/2023: NEW UNIVERSAL MILLING MACHINE WITH INTEGRATED DIGITAL POSITION INDICATOR - OPTImill MT 200

We modernize our machinery once again! A new universal milling machine OPTImill MT 200 with integrated digital position indicator from BOUKAL company can machine parts with max. dimensions 1100 x 300 x 500mm at 0,02mm precision level.

01/2022: NEW CNC LATHE MACHINE - XYZ PROTURN SLX 425 PUT INTO SERVICE

01/2022: NEW CNC LATHE MACHINE - XYZ PROTURN SLX 425 PUT INTO SERVICE

We have expanded our machine park! A new CNC lathe machine - XYZ PROTURN SLX 425 from REXIM, s.r.o. company - was added to our machinery in January. New CNC can machine parts with dimensions: Ømax = 450 mm, Lmax = 1200 mm.

12/2021: MOBILE WELDING SMOKE EXTRACTORS REPLACED BY TCL SMOKE EXTRACTION SYSTEM

12/2021: MOBILE WELDING SMOKE EXTRACTORS REPLACED BY TCL SMOKE EXTRACTION SYSTEM

At the end of 2021, the old welding smoke point extractors were replaced by a new full fledged full-area TCL smoke extraction system from the company WELDING OSTRAVA - WELDO, s.r.o. The TCL system uses a suction pipeline that is installed under the hall ceiling. The welding smoke is fed to the filter unit, where it is freed of dust. The clean air is then blown back into the hall space. This has improved the working conditions of our employees.

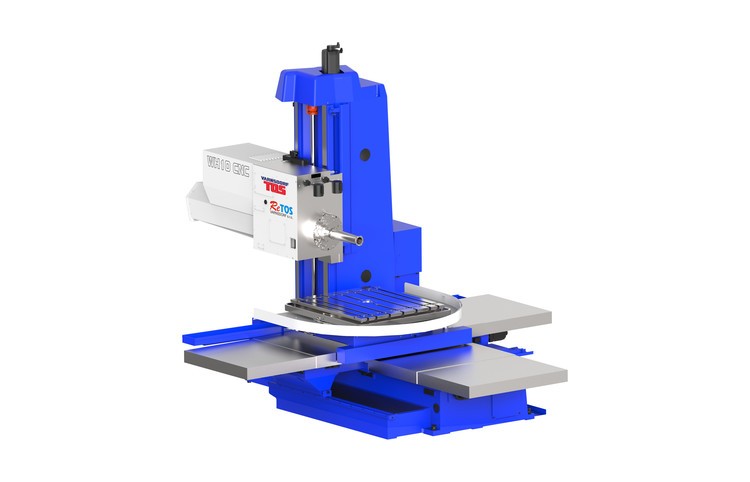

01/2021: NEW HORIZONTAL BORING & MILLING MACHINE WH 10 CNC PUT INTO SERVICE

01/2021: NEW HORIZONTAL BORING & MILLING MACHINE WH 10 CNC PUT INTO SERVICE

Resulting from the successful implementation of the Eurofund project a new horizontal boring & milling machine WH 10 CNC was purchased from the Czech manufacturer TOS VARNSDORF. The machine was put into operation in January - after an unplanned delay caused by the COVID pandemic. The company now has new opportunities in the technological areas of drilling and milling.

07/2020: NEW HORIZONTAL CNC – MILLING MACHINE

07/2020: NEW HORIZONTAL CNC – MILLING MACHINE

On the basis of the already approved Euro-project, the company will receive a grant from the EU funds for the purchase of a new WH 10 CNC – horizontal milling machine. Specifications of the new machine are currently submitted for production at the TOS VARNSDORF company. We expect the machine to be operational in July 2020.

11/2019: INCREASING THE QUALITY AND EFFICIENCY OF THE PRODUCTION PROCESS

11/2019: INCREASING THE QUALITY AND EFFICIENCY OF THE PRODUCTION PROCESS

On November 20th, 2019 the Contract on the provision of a non-repayable financial contribution No.: 322/2018-2060-2230-R333 between OMEGA METAL and Ministry of Economy of the Slovak Republic entered into force. Our company has received a grant from the European Regional Development Fund in the amount of € 164,228.10 to support intelligent innovations (automation) of the production process. The Euro-project will result in the co-financing of a new WH 10 CNC – horizontal milling machine.

10/2019: ORNAMENTAL PLANT GARDENING

10/2019: ORNAMENTAL PLANT GARDENING

In October 2019 we beautified the corporate exterior by planting some ornamental greenery and lawn. Decorative landscaping gravel and solitary boulders were also placed.

09/2019: NEW PARKING LOT

09/2019: NEW PARKING LOT

In September 2019, we built a new parking lot in front of the company building in order to have suitable parking conditions. There is a total of 32 parking places available, 4 of which are reserved for visits. The capacity of the parking lot thus fully satisfies the needs of our employees as well as our visitors.

06/2019: IMPLEMENTATION OF SOLIDCAM AND SOLIDWORKS

06/2019: IMPLEMENTATION OF SOLIDCAM AND SOLIDWORKS

In June 2019, with the help of Schier Technik Slovakia company, we implemented a solution for optimizing CNC programming (iMachining) and 3D modeling. SolidCAM is a fully integrated computer-aided machining system in the SolidWorks CAD environment. SolidCAM provides functions for defining machining operations, for simulating and controlling the machining, and for generating CNC programs. SolidWorks tools allow us to work with geometry – part/assembly modeling and drawing design.

05/2019: THERMAL CLADDING AND NEW FACADE

05/2019: THERMAL CLADDING AND NEW FACADE

For aesthetic as well as economic reasons, in May 2019, both – thermal insulation and a new facade – were made on the company building. Since 1970s, when the company building was built, the original facade has not yet been renovated. The new blue facade represents our corporate color.